Motor magnet permanen

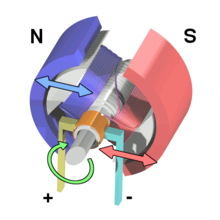

A permanent magnet motor is a type of electric motor that uses permanent magnets in addition to windings on its field, rather than windings only.

Use in electric vehicles

This type of motor is used in GM's Chevrolet Bolt[1] and Volt, and the rear wheel drive of Tesla's Model 3.[2] Recent dual motor Tesla models use a combination of a permanent magnet motor at the back and traditional induction motor at the front.[3]

Permanent magnet motors are more efficient than induction motor or motors with field windings for certain high-efficiency applications such as electric vehicles. Tesla's chief motor designer was quoted discussing these advantages, saying:

It's well known that permanent magnet machines have the benefit of pre-excitation from the magnets, and therefore you have some efficiency benefit for that. Induction machines have perfect flux regulation and therefore you can optimize your efficiency. Both make sense for variable-speed drive single-gear transmission as the drive units of the cars. So, as you know, our Model 3 has a permanent magnet machine now. This is because for the specification of the performance and efficiency, the permanent magnet machine better solved our cost minimization function, and it was optimal for the range and performance target. Quantitatively, the difference is what drives the future of the machine, and it's a trade-off between motor cost, range and battery cost that is determining which technology will be used in the future.[2]

Permanent magnet motors consist of two main types SPM motors (Surface Permanent magnets motors) and IPM motors (Internal Permanent magnets motors). The main difference is that SPM motors place the magnets on the outside of the rotor and IPM motors place their magnets on the inside of the motor. There are a few benefits to placing the magnetics internally such as structural integrity and reducing Back EMF. Since holes must be cut into the rotor for the placement of the magnets this creates areas of high reluctance allowing carmakers to also use some of the benefits of reluctance motors as well as permanent magnet motors.[4]

Back EMF

This effect is not unique to permanent magnet motors. An induction motor will also suffer from this effect however in an induction motor the fields from the rotor will decrease as speed increases. A permanent magnet motor generates in its own constant field. This means that as speed increases a voltage is induced linearly to the speed on the stator. This voltage will be negative to the voltage provided to the motor and thus will be a loss to the overall system. [4]

Environmental and supply concerns

Permanent magnet motors utilize several types of permanent magnet materials, including hard ferrites, alnico, samarium cobalt and neodymium iron boron. Hard ferrites are the permanent magnet material most commonly found (by weight) in permanent magnet motors. This is due to their low cost. If other factors are important (size, temperature capability, calibration, coercivity, etc.), motor design engineers typically use one of the other permanent magnet materials.

Rare earth production has the consequence of generating waste with elevated radioactivity compared to the natural radioactivity of the ores (waste that is referred to by the US EPA as TENORM, or Technologically Enhanced Naturally Occurring Radioactive Materials). China, the top producer of neodymium, restricted shipments to Japan in 2010 during a controversy over disputed ownership of islands. China imposed strict export quotas on several rare earth metals, saying it wanted to control pollution and preserve resources. The quotas were lifted in 2015. Although neodymium is relatively abundant, global demand for neodymium outstripped production by about 10% in 2017.[3]

See also

References

- ^ Drive Unit and Battery at the Heart of Chevrolet Bolt EV, 11 January 2016

- ^ a b Tesla's top motor engineer talks about designing a permanent magnet machine for Model 3, 27 February 2018

- ^ a b "Tesla's electric motor shift to spur demand for rare earth neodymium". Reuters (dalam bahasa Inggris). 2018-03-13. Diakses tanggal 2019-08-24.

- ^ a b "Understanding permanent magnet motors" (dalam bahasa Inggris). 2017-01-31. Diakses tanggal 2022-04-16.